Canterbury Trap Intl Ltd is dedicated to providing competitive clay target shooters with the most robust, modern and versatile clay target throwing machines, in the world.

Our machines work equally well in the hottest or coldest of conditions – freezing winters or blazing summers are irrelevant – and deliver hundreds of thousands of targets with minimal maintenance.

We are constantly looking to implement the most modern technology in our pursuit to supply customers needs and our link with Canterbury Voice Release Intl ltd (the world’s largest supplier of clay target voice release systems) means our electronics are user-friendly, robust and designed to meet shooters needs.

We look at this sport with a fresh vision and the development of the world’s first automatic single-trap Bunker (Trench) machine epitomizes this approach. For those Olympic trap shooters who need to practice their sport, then this new machine will exceed their dreams! Touch button control gives access to all programs / traps at an instance.

We look forward to continuing our policy of “innovation & versatility”.

Trapmaster Standard

Standard features

- Throws single and double targets

- Change from single to doubles in seconds

- 600 capacity target hopper

- Wall mounted control system with sleep mode and target counter

- Targets thrown from a Western 1524 arm

- Gentle target delivery system via elevator

- Accurate target placement and presentation

- Oscillation 34 and 44 deg with unreadable interrupt and sleep mode

- Instantaneous solenoid release system

- Manual pull cord 33M

- Fully compatible with all Canterbury Voice Release products

- 2 second cycle time

- Remote safety

- Simple distance,height,and Windage adjustments

- Windage adjustment as standard

- Available in 240V and 110V options

- 34 inches high / 870mm

- CT45 Continental / Wobble option

- All steel construction, zinc plated for corrosion protection and powdercoated.

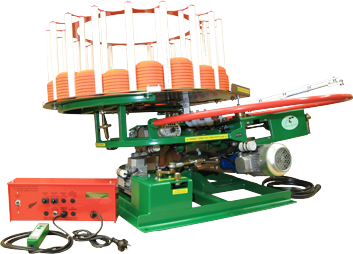

Trapmaster Continental

● Standard features

● Throws single and double targets

● Change from single to doubles in seconds

● 600 capacity target hopper

● Wall mounted control system with

sleep mode and target counter

● Targets thrown from a Western 1524 arm

● Gentle target delivery system via elevator

● Accurate target placement and presentation

● Oscillation with unreadable interrupt

● Fully compatible with all

Canterbury Voice Release products

● 2 Second cycle time

● Remote safety

● Simple distance, height, and windage adjustments

● Windage adjustment as standard

● Power 240V 50Hz or 110V 60Hz

● 34 inches high / 870mm

● Shipping weight 240kg

Crusader Skeet

Standard features

- 400 capacity target hopper

- Wall mounted control system with target counter

- Double knife target splitter

- Gentle target delivery system

- Consistent target placement and presentation

- Instantaneous solenoid release system

- Throwing distance up to 100M

- Manual pull cord 33M

- Fully compatible with all Canterbury Voice Release products

- 2 Second cycle time

- Remote safety

- Simple distance,height,and windage adjustments

- Windage adjustment as standard

- Available in 240V and 110V options

- 38 inches high / 970mm

- All steel construction, zinc plated for corrosion protection and powdercoated

Windage adjustment is standard on all Crusader traps. This enables the target to be leveled in the sky, and reduce target curl due to crosswinds.

Distance and height are also easily adjusted.

The Crusader Control systems is easy to use and features a LCD displaying the target count and machine cycles.

A remote safety pendent with isolation switch and manual target release is also a feature on all Canterbury Traps.

Crusader DTL

Standard features

- 300 capacity target hopper

- Wall mounted control system with sleep mode and target counter

- Oscillation 34 / 44 deg with unreadable interrupt and sleep mode

- Double knife target splitter

- Gentle target delivery system

- Consistent target placement and presentation

- Throwing distance up to 100M

- Instantaneous solenoid release system

- Manual pull cord 33M

- Fully compatible with all Canterbury Voice Release products

- 2 Second cycle time

- Remote safety

- Simple distance,height,and windage adjustments

- Windage adjustment as standard

- Available in 240V and 110V options

- 38 inches high / 970mm

- All steel construction, zinc plated for corrosion protection and powdercoated

- Optional mini hopper available to suit 75mm Dia targets

Windage adjustment is standard on all Crusader traps. This enables the target to be leveled in the sky, and reduce target curl due to crosswinds.

Distance and height are also easily adjusted.

The Crusader Control systems is easy to use and features a LCD displaying the target count and machine cycles.

A remote safety pendent with isolation switch and manual target release is also a feature on all Canterbury Traps.

Crusader Continental

Standard features

- 300 capacity target hopper

- Wall mounted control system with sleep mode and target counter

- Horizontal oscillation 34 / 44 / 70 deg with unreadable interrupt and sleep mode

- Continental / ABT, vertical oscillation

- Double knife target splitter

- Gentle target delivery system

- Consistent target placement and presentation

- Throwing distance up to 100M

- Instantaneous solenoid release system

- Manual pull cord 33M

- Fully compatible with all Canterbury Voice Release products

- 2 Second cycle time

- Remote safety

- Simple distance,height,and windage adjustments

- Windage adjustment as standard

- Available in 240V and 110V options

- 41 inches high / 1050mm

- All steel construction, zinc plated for corrosion protection and powdercoated

- Optional mini hopper available to suit 75mm Dia targets

Windage adjustment is standard on all Crusader traps. This enables the target to be leveled in the sky, and reduce target curl due to crosswinds.

Distance and height are also easily adjusted.

The Crusader Control systems is easy to use and features a LCD displaying the target count and machine cycles.

A remote safety pendent with isolation switch and manual target release is also a feature on all Canterbury Traps.

Crusader Mini Hopper

The Mini hopper will fit onto all Crusader traps.

With 300 + target capacity it’s fitted in minutes and includes a specially designed Flip Flop plate to take the mini targets.

Will accept 75mm Dia targets.

Crusader Throwing Arms

The Crusader can be supplied with two different types of rubber fitted to the throwing arm.

The soft green rubber is designed for standard DTL and Skeet targets. It grips the driving ring on the target and imparts more spin into the target improving target stability in flight.

The Harder red rubber is designed for ISSF Trap and Skeet targets. It imparts it’s energy into throwing the target the 76M required while maintaining leaf spring life due to reduced spring tension.

Manuals

The file’s listed are in Adobe’s Portable Document Format (PDF). You require Adobe’s Acrobat Reader to access the file. This software is available free of charge from the Internet and can be found at: https://acrobat.adobe.com/nz/en/acrobat/pdf-reader.html

Trapmaster Owners Manual 13 - 2.71MB

Crusader Owners Manual Rev 12 July 2015 - 1.7MB

2009 Crusader Owners Manual - 3.16MB

Canterbury Trapmaster - 0.66MB

Trapmaster (TM79) Replacement Instructions - 0.43MB

Head Office

Postal Address

Canterbury Trap International Ltd

C/- P O BOX 14035

Christchurch Airport

Christchurch 8544

New Zealand

Email cti@prometal.co.nz

Telephone +64 3 384 4524

Fax +64 3 348 4285

Delivery Address

20 Logistics Drive

Russley Business Park 8051

Christchurch

New Zealand

Australia

Peter Fitzalan

New South Wales

Dubbo 2830

Telephone 02 6885 6099

Mobile 04 2885 6099

Email pbfitzalan@bigpond.com

New Zealand

Craftsman Sports

For Sales & Parts :- Sheryl on 0274 200 620 or

Email sheryl@jaytod.co.nz

For Servicing :- Todd on 021 351 463 or

Email todd@jaytod.co.nz

Telephone 0274 200 620

Mobile 0274 200 620

Website https://www.craftsmansports.co.nz/

Email sheryl@jaytod.co.nz